Product Description

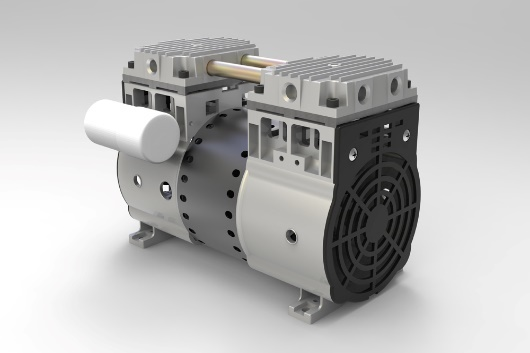

Topsflo Small High Performance High Pressure Diaphragm DC Air Pump, Mini Membrane Brush DC Vacuum Pump

Description:

CZPT micro diaphragm pumps and compressors are based on a simple principal, the circular power from the motor is converted into oscillating movement by an eccentric, which moves up and down its central point, this motion is then transferred to a diaphragm by means of a connecting rod, an elastic diaphragm, which in conjunction with an inlet and outlet valve creates a pumping action.

The TM 40 Series offers multiple component configurations allowing them to be used for either vacuum operation, pressure operation, or alternating vacuum and pressure operations.The innovative, compact design incorporates leading edge technologies that allow it to operate harder, quieter and longer, reliabler, highly efficient.

TM 40 pumps can be mounted in any position and can deliver up to 13 l/min, 16L/min (dual head) depending on the model and will operate against pressures of up to 280Kpa.

Specification:

| Model |

Pressure Pump | Vacuum Pump | Rated Voltage | No-load Current | Max Pressure | Max Vacuum | Max Flow |

| (Item Number) | (Item Number) | (Vdc) | (A) | (KPa) | (KPa) | (L/min) | |

| TM40-B | TM40A-B01-12-P22013 | TM40A-B01-12-V8013 | 12 | 0.7 | 220 | -80 | 13 |

| TM40-B02-12-P28016 | TM40A-B02-12-V8016 | 12 | 1.2 | 280 | -80 | 16 | |

| ” P ” means pressure pump, ” V ” means vacuum pump, “12/24” means different voltages optional. | |||||||

| Pump Weight:280g; Pump Size:86*mm*65mm*40.5mm; Inlet&Outlet:OD 6.5mm/ID 3.4mm,hose suggestion:ID 5.0mm | |||||||

| Materials:pump head Nylon, membrane EPDM, valve EPDM Motor type and code:”B”means economical brush DC motor (reference lifetime ≥1,000hours) |

|||||||

Features:

Highest Performance/Size Ratio

Innovative and efficient engineering designs enable the TM 40 Series to push the performance envelope in a lightweight, compact size.

Performs Quieter

Optimized head, chamber, and flow path reduce noise without compromising performance.

Lasts Reliably Longer

Uncontaminated flow

no contamination of the media due to oil-free operation

Little vibration

Because of leading edge technologies, top quality bearing, superior brushless motor

High level of gas tightness

thanks to stress-optimised structured diaphragm, newly-designed valves and sealing systems, precise placement of the pump head

Extreme chemical resistance

The use of chemically resistant materials optional such as PTFE FKM or other ,material combinations for the parts which allows the corrosive gas to be pumped.

Optimal solution for your application

a wide standard range of materials, motors , voltages configurates multiple components system selected

Typical Application:

Industrial pressure and vacuum applications

Portable Analytical Instruments

Medical Diagnostic Equipment

Air Quality Sampling Monitors

Respiration Monitors

Gas or Odor Leak Detectors

Dimension(mm) & Curve:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Head Nylon, Membrane EPDM / PTFE, Valve EPDM / FPM |

|---|---|

| Power: | Electric |

| Function: | Electronic Type |

| Motor: | DC Brush,Motor |

| Materials: | Pump Head Nylon, Membrane EPDM / PTFE, Valve EPDM |

| Life-Time: | 1200hour |

| Customization: |

Available

|

|

|---|

How to check the vacuum pump

A vacuum pump is a machine that draws gas molecules from a volume and maintains a partial vacuum. Its main job is to create a relative vacuum within the stated capabilities. If your vacuum pump isn’t working properly, it may need service. Read on to learn more about the types of vacuum pumps and how to check them.

Principle of industrial vacuum pump

Industrial vacuum pumps are used in industrial processes that require vacuum. These pumps are designed to generate, improve and maintain vacuum. Learn about the different types of industrial vacuum technology. You can start by reading about the most common types of industrial vacuum pumps. These pumps can be used in a variety of industrial processes from cleaning to manufacturing.

Regardless of the technology used to manufacture these pumps, the basic principles behind their operation are the same. The speed and mass flow of the pump will determine its capacity and suitability. A faster flow rate will minimize the time it takes for the machine to empty. Another important factor to consider is the type of vacuum you need.

A liquid ring vacuum pump is an industrial pump that uses a ring of liquid to form a seal. This type of pump is best suited for applications with high vapor loads and high liquid carry-over. Liquid ring vacuum pumps can be divided into two categories: liquid ring vacuum pumps and scroll vacuum pumps.

Industrial vacuum pumps work by removing gas molecules from a chamber. The partial vacuum created allows material to flow through the void. As more molecules are removed, the pressure in the chamber decreases, releasing energy that can be used for a variety of different purposes.

The most common use of industrial vacuum pumps is for electric lights. In these lamps, a vacuum pump removes the gas, causing the bulb to light up. Energy from the vacuum is also used in aircraft to power instruments. In addition to powering industrial vacuum cleaners, they are used in a variety of other environments.

High-performance industrial vacuum systems require specific materials that can withstand extreme pressure. This means that the materials used in these systems need to be properly checked. They must also be free of organic debris and other contaminants before they can be safely placed in the chamber.

Types of vacuum pumps

There are various types of vacuum pumps. Which one to choose should depend on the purpose of the pump and the degree of vacuum that must be achieved. It is mainly divided into three categories: rough vacuum or low vacuum, high vacuum and ultra-high vacuum. They all have varying degrees of scarcity. The higher the pressure, the fewer molecules per cubic centimeter. This in turn improves vacuum quality.

The vacuum pump is critical to the operation of the vacuum system. These devices are divided into three main categories according to their working pressure range. These pumps have different characteristics and technologies that make them ideal for specific applications. The choice of vacuum pump required for a particular application depends on how much vacuum you need, and how much power you are willing to spend.

Vacuum pumps are used in a variety of industrial and scientific processes. Their main function is to remove gas molecules from the sealed volume, leaving a partial vacuum. There are many different types of vacuum pumps, including rotary piston, liquid ring and scroll vacuum pumps. In addition, turbomolecular pumps are used.

Dry vacuum pumps are more expensive than wet vacuum pumps. Wet vacuum pumps use oil as their lubricating fluid. Different types of oils are used depending on the application. Some wet pumps have additional features, including contaminant filtration. However, wet systems have one major disadvantage: the contact between oil and fluid. To avoid this, oil separators are usually used.

There are several different types of vacuum pumps. The basic type is the positive displacement pump. It operates by expanding the chamber and removing gas molecules. The intake valve draws fluid into the chamber, while the exhaust valve opens when the chamber is at maximum expansion. This cycle repeats several times per second. Positive displacement pumps are often used in multistage vacuum systems.

Maintenance of vacuum pump

Regular maintenance is very important to ensure the long-term effective use of the vacuum pump. One way to ensure proper pump performance is to change the oil regularly. Pump oil may be contaminated by vapor condensation. To avoid this problem, close the inlet valve for 20 to 30 minutes before applying vacuum. It is also important to install an inlet cold trap to protect the pump from corrosive vapors.

Another way to prolong the life of your vacuum pump is to periodically remove any solvent in it. This step reduces internal corrosion and prevents premature pump failure. During maintenance, be sure to disconnect the power supply to the vacuum pump. After cleaning, store it in a dry and safe place. The pump should also be disposed of in accordance with local regulations.

Vacuum pumps may require frequent oil changes, especially when used in wet chemistry. The standard rule is to change the oil after 3,000 hours of use, but some pumps require more frequent oil changes. It is also important to clean the oil regularly, as dirty or discolored oil can affect the performance of the pump.

Vacuum pumps are often equipped with on-site glass to allow the user to visually check the oil level. Clean oil will appear transparent, while dirty oil will appear darker. Frequent oil changes are essential, as oil changes can help spot various potential problems. Changes in vacuum pump performance or strange noises are also good indicators of a problem.

After an oil change, the vacuum pump should be cleaned thoroughly with a soft cloth and mild degreaser. Oil changes should take less than ten minutes, and they will extend the life of your equipment. Additionally, the outside of the pump should be wiped with a cloth or rag.

The pump must be properly vented to avoid internal corrosion. If possible, place the pump away from hot equipment or rooms. Overheating can reduce the viscosity of the oil and cause premature pump failure. In addition, it can lead to overwork of other expensive scientific equipment. Heat can also cause cracked rubber parts and oil leaks.

Signs of damage to the vacuum pump

A bad vacuum pump can cause a variety of automotive problems, including poor fuel economy, difficult braking, undercarriage oil leaks, and faulty air conditioning. If any of these problems occur, call a mechanic to check your vehicle’s vacuum pump. You can also check the air conditioner and brake pedal to see if they are working properly.

A loud noise from the pump can also be a symptom of a malfunction. These noises are often caused by the aging and accumulated wear of specific components. If this is the case, the diaphragm, valve plate or seals may need to be replaced. However, if the noise is coming from bearings or other areas, more extensive repairs may be required. Additionally, dust and other contaminants can enter the pump chamber, which can degrade pump performance.

If the vacuum pump won’t start, it could be a blown fuse or a power or voltage problem. Other common causes are flow restrictions or improper installation at the entrance. Also, the vacuum pump may be damaged or the capacitors may be of poor quality. It’s not always easy to tell if a vacuum pump is leaking oil, but a greasy transmission can indicate a vacuum pump failure.

A leaking vacuum pump can also hiss when the car’s engine is running. If you hear it, check the hoses and connections to make sure there are no leaks. A vacuum leak may indicate a faulty vacuum pump, so you need to replace it as soon as possible.

Checking end pressure is easy, but a pressure gauge can also serve as a sign. You can also check for pump vibration by running a short procedure. Excessive vibration can be subtle, but it can greatly affect your process. If you notice excessive pump vibration, you should contact a professional immediately.

Poor pump performance can cause many problems for your company. A bad vacuum pump not only wastes material, it also damages your tools and reputation.

editor by Dream 2024-05-09

China best Qby-15 Mini Air Operated Pneumatic Diaphragm Vacuum Pump vacuum pump engine

Product Description

Product Description

Overview

Pneumatic diaphragm pump is a new type of conveyor machinery, adopts compressed air as power source, suitable for various corrosive liquid, with particles liquid, high viscosity and volatile, inflammable, poisonous liquid. The main characteristic of this pump is no priming water needed, can pumping the medium that easy to transport. High suction head, adjustable delivery head, fire and explosion proof.

Working Principle

In the 2 symmetrical pump chamber equipped with a diaphragm, which is connected by a center couplet stem. Compressed air comes in from pump inlet valve, and enter into 1 cavity, push the diaphragm movement, and gases emitted from another cavity. Once to the destination, gas distribution components will automatically compressed air into another chamber, push the diaphragm to the opposite direction, thus make 2 diaphragm continuous synchronization to reciprocating movement.

Compressed air goes into the valve, make the diaphragm to the right movement, and chamber suction make medium enter into, push the ball into the room, ball valve shuts down due to inhalation, Mediums discharged by extrusion, and opened the ball valve and at the same time close the ball valve, prevent back flow, thus to make medium ceaseless from the entrance inhaled, exit eduction.

Main Advantages

1, Due to the use of air power, the flow automatically changed according to export resistance. Which is suitable for high viscosity fluid.

2, In inflammable and explosive environment, the pump is reliable and low cost, won’t produce spark and not overheat.

3, The pump volume is small, easy to move, no foundation needed, convenient installation and economy. Can be used as mobile conveying pump.

4, Where there are dangers, corrosive materials processing, diaphragm pump can be separated completely with outside.

5, The pump shearing force is low, physical effect to medium is small, can be used for conveying unstable chemistry fluid.

Product Parameters

|

Name |

Model |

Diameters (mm) |

Flow(m3/h) |

Head(m) |

NPSH(m) |

Solids Size φ(mm) |

Air pressure (kgf/cm2) |

|

Diaphragm |

QBY-10 |

10 |

0.8 |

50 |

5 |

1 |

2-7 |

|

QBY-15 |

15 |

1 |

50 |

5 |

1 |

2-7 |

|

|

QBY-25 |

25 |

2.4 |

50 |

7 |

2.5 |

2-7 |

|

|

QBY-40 |

40 |

8 |

50 |

7 |

4.5 |

2-7 |

|

|

QBY-50 |

50 |

12 |

50 |

7 |

8 |

2-7 |

|

|

QBY-65 |

65 |

16 |

50 |

7 |

8 |

2-7 |

|

|

QBY-80 |

80 |

24 |

50 |

7 |

10 |

2-7 |

|

|

QBY-100 |

100 |

30 |

50 |

7 |

10 |

2-7 |

Packaging & Shipping

Packing Details : One pump in One plywood case

Delivery Details : 30 days after order confirmation

Company Profile

ZheZheJiang oto Pump Industrial Co., Ltd. is a professional pump manufacturer integrating R&D, manufacturing, sales and service as a whole, which has been certified by ISO9001 international quality management system.

Located in Xihu (West Lake) Dis.a Industrial Park, ZheJiang , CHINAMFG Pump Industrial possesses 2 manufacturing bases in ZheJiang and ZHangZhoug. Since our inception, CHINAMFG Pump Industrial has been committed to the innovation and development of various pumps. Our leading products include self-priming trash pump, centrifugal pump, submersible pump, diaphragm pump, vacuum pump, diesel pump, fire pump, etc.

FAQ

Q: Can I chat with you online? What is your company official website?

Q: What type of company CHINAMFG is?

A: CHINAMFG is a manufacture and trading company, has factories in ZheJiang and ZHangZhoug, with export and import license.

Q: What kinds of pumps do you supply?

A: Our products including self-priming trash pump, centrifugal pump, diaphragm pump, submersible pump, chemical pump, oil pump, diesel pump, fire fighting pump, etc.

Q: What is your payment terms?

A: Alibaba Trade Assurance, Western Union, Paypal, T/T, L/C, etc.

Q: Can you provide OEM, ODM service?

A: Yes. We have factories in ZheJiang and ZHangZhoug, we can make products according to your requirements.

Q: Why should we buy from you?

A: We are committed to provide best quality products at minimum delivery time and competitive price. We believe this is what customer wants. We are satified until customers are.

Q: What is your warranty period?

A: We provide 1 year of unconditional warranty on our products for the manufacturing defects.

Q: What about delivery time?

A: Normally our production time is within 2 weeks. Please confirm before order.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Provided |

|---|---|

| Warranty: | 1year |

| Rated Current: | 11-15A |

| Voltage: | 380V |

| Material: | Aluminum Alloy |

| Power: | Pneumatic |

| Samples: |

US$ 3000/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How Do You Maintain and Troubleshoot Vacuum Pumps?

Maintaining and troubleshooting vacuum pumps is essential to ensure their optimal performance and longevity. Here’s a detailed explanation:

Maintenance of Vacuum Pumps:

1. Regular Inspection: Perform regular visual inspections of the pump to check for any signs of damage, leaks, or abnormal wear. Inspect the motor, belts, couplings, and other components for proper alignment and condition.

2. Lubrication: Follow the manufacturer’s guidelines for lubrication. Some vacuum pumps require regular oil changes or lubrication of moving parts. Ensure that the correct type and amount of lubricant are used.

3. Oil Level Check: Monitor the oil level in oil-sealed pumps and maintain it within the recommended range. Add or replace oil as necessary, following the manufacturer’s instructions.

4. Filter Maintenance: Clean or replace filters regularly to prevent clogging and ensure proper airflow. Clogged filters can impair pump performance and increase energy consumption.

5. Cooling System: If the vacuum pump has a cooling system, inspect it regularly for cleanliness and proper functioning. Clean or replace cooling components as needed to prevent overheating.

6. Seals and Gaskets: Check the seals and gaskets for signs of wear or leakage. Replace any damaged or worn seals promptly to maintain airtightness.

7. Valve Maintenance: If the vacuum pump includes valves, inspect and clean them regularly to ensure proper operation and prevent blockages.

8. Vibration and Noise: Monitor the pump for excessive vibration or unusual noise, which may indicate misalignment, worn bearings, or other mechanical issues. Address these issues promptly to prevent further damage.

Troubleshooting Vacuum Pump Problems:

1. Insufficient Vacuum Level: If the pump is not achieving the desired vacuum level, check for leaks in the system, improper sealing, or worn-out seals. Inspect valves, connections, and seals for leaks and repair or replace as needed.

2. Poor Performance: If the pump is not providing adequate performance, check for clogged filters, insufficient lubrication, or worn-out components. Clean or replace filters, ensure proper lubrication, and replace worn parts as necessary.

3. Overheating: If the pump is overheating, check the cooling system for blockages or insufficient airflow. Clean or replace cooling components and ensure proper ventilation around the pump.

4. Excessive Noise or Vibration: Excessive noise or vibration may indicate misalignment, worn bearings, or other mechanical issues. Inspect and repair or replace damaged or worn parts. Ensure proper alignment and balance of rotating components.

5. Motor Issues: If the pump motor fails to start or operates erratically, check the power supply, electrical connections, and motor components. Test the motor using appropriate electrical testing equipment and consult an electrician or motor specialist if necessary.

6. Excessive Oil Consumption: If the pump is consuming oil at a high rate, check for leaks or other issues that may be causing oil loss. Inspect seals, gaskets, and connections for leaks and repair as needed.

7. Abnormal Odors: Unusual odors, such as a burning smell, may indicate overheating or other mechanical problems. Address the issue promptly and consult a technician if necessary.

8. Manufacturer Guidelines: Always refer to the manufacturer’s guidelines and recommendations for maintenance and troubleshooting specific to your vacuum pump model. Follow the prescribed maintenance schedule and seek professional assistance when needed.

By following proper maintenance procedures and promptly addressing any troubleshooting issues, you can ensure the reliable operation and longevity of your vacuum pump.

Can Vacuum Pumps Be Used for Chemical Distillation?

Yes, vacuum pumps are commonly used in chemical distillation processes. Here’s a detailed explanation:

Chemical distillation is a technique used to separate or purify components of a mixture based on their different boiling points. The process involves heating the mixture to evaporate the desired component and then condensing the vapor to collect the purified substance. Vacuum pumps play a crucial role in chemical distillation by creating a reduced pressure environment, which lowers the boiling points of the components and enables distillation at lower temperatures.

Here are some key aspects of using vacuum pumps in chemical distillation:

1. Reduced Pressure: By creating a vacuum or low-pressure environment in the distillation apparatus, vacuum pumps lower the pressure inside the system. This reduction in pressure lowers the boiling points of the components, allowing distillation to occur at temperatures lower than their normal boiling points. This is particularly useful for heat-sensitive or high-boiling-point compounds that would decompose or become thermally degraded at higher temperatures.

2. Increased Boiling Point Separation: Vacuum distillation increases the separation between the boiling points of the components, making it easier to achieve a higher degree of purification. In regular atmospheric distillation, the boiling points of some components may overlap, leading to less effective separation. By operating under vacuum, the boiling points of the components are further apart, improving the selectivity and efficiency of the distillation process.

3. Energy Efficiency: Vacuum distillation can be more energy-efficient compared to distillation under atmospheric conditions. The reduced pressure lowers the required temperature for distillation, resulting in reduced energy consumption and lower operating costs. This is particularly advantageous when dealing with large-scale distillation processes or when distilling heat-sensitive compounds that require careful temperature control.

4. Types of Vacuum Pumps: Different types of vacuum pumps can be used in chemical distillation depending on the specific requirements of the process. Some commonly used vacuum pump types include:

– Rotary Vane Pumps: Rotary vane pumps are widely used in chemical distillation due to their ability to achieve moderate vacuum levels and handle various gases. They work by using rotating vanes to create chambers that expand and contract, enabling the pumping of gas or vapor.

– Diaphragm Pumps: Diaphragm pumps are suitable for smaller-scale distillation processes. They use a flexible diaphragm that moves up and down to create a vacuum and compress the gas or vapor. Diaphragm pumps are often oil-free, making them suitable for applications where avoiding oil contamination is essential.

– Liquid Ring Pumps: Liquid ring pumps can handle more demanding distillation processes and corrosive gases. They rely on a rotating liquid ring to create a seal and compress the gas or vapor. Liquid ring pumps are commonly used in chemical and petrochemical industries.

– Dry Screw Pumps: Dry screw pumps are suitable for high-vacuum distillation processes. They use intermeshing screws to compress and transport gas or vapor. Dry screw pumps are known for their high pumping speeds, low noise levels, and oil-free operation.

Overall, vacuum pumps are integral to chemical distillation processes as they create the necessary reduced pressure environment that enables distillation at lower temperatures. By using vacuum pumps, it is possible to achieve better separation, improve energy efficiency, and handle heat-sensitive compounds effectively. The choice of vacuum pump depends on factors such as the required vacuum level, the scale of the distillation process, and the nature of the compounds being distilled.

Can Vacuum Pumps Be Used in Food Processing?

Yes, vacuum pumps are widely used in food processing for various applications. Here’s a detailed explanation:

Vacuum pumps play a crucial role in the food processing industry by enabling the creation and maintenance of vacuum or low-pressure environments. They offer several benefits in terms of food preservation, packaging, and processing. Here are some common applications of vacuum pumps in food processing:

1. Vacuum Packaging: Vacuum pumps are extensively used in vacuum packaging processes. Vacuum packaging involves removing air from the packaging container to create a vacuum-sealed environment. This process helps extend the shelf life of food products by inhibiting the growth of spoilage-causing microorganisms and reducing oxidation. Vacuum pumps are used to evacuate the air from the packaging, ensuring a tight seal and maintaining the quality and freshness of the food.

2. Freeze Drying: Vacuum pumps are essential in freeze drying or lyophilization processes used in food processing. Freeze drying involves removing moisture from food products while they are frozen, preserving their texture, flavor, and nutritional content. Vacuum pumps create a low-pressure environment that allows frozen water to directly sublimate from solid to vapor, resulting in the removal of moisture from the food without causing damage or loss of quality.

3. Vacuum Cooling: Vacuum pumps are utilized in vacuum cooling processes for rapid and efficient cooling of food products. Vacuum cooling involves placing the food in a vacuum chamber and reducing the pressure. This lowers the boiling point of water, facilitating the rapid evaporation of moisture and heat from the food, thereby cooling it quickly. Vacuum cooling helps maintain the freshness, texture, and quality of delicate food items such as fruits, vegetables, and bakery products.

4. Vacuum Concentration: Vacuum pumps are employed in vacuum concentration processes in the food industry. Vacuum concentration involves removing excess moisture from liquid food products to increase their solids content. By creating a vacuum, the boiling point of the liquid is reduced, allowing for gentle evaporation of water while preserving the desired flavors, nutrients, and viscosity of the product. Vacuum concentration is commonly used in the production of juices, sauces, and concentrates.

5. Vacuum Mixing and Deaeration: Vacuum pumps are used in mixing and deaeration processes in food processing. In the production of certain food products such as chocolates, confectioneries, and sauces, vacuum mixing is employed to remove air bubbles, achieve homogeneity, and improve product texture. Vacuum pumps aid in the removal of entrapped air and gases, resulting in smooth and uniform food products.

6. Vacuum Filtration: Vacuum pumps are utilized in food processing for vacuum filtration applications. Vacuum filtration involves separating solids from liquids or gases using a filter medium. Vacuum pumps create suction that draws the liquid or gas through the filter, leaving behind the solid particles. Vacuum filtration is commonly used in processes such as clarifying liquids, removing impurities, and separating solids from liquids in the production of beverages, oils, and dairy products.

7. Marinating and Brining: Vacuum pumps are employed in marinating and brining processes in the food industry. By applying a vacuum to the marinating or brining container, the pressure is reduced, allowing the marinade or brine to penetrate the food more efficiently. Vacuum marinating and brining help enhance flavor absorption, reduce marinating time, and improve the overall taste and texture of the food.

8. Controlled Atmosphere Packaging: Vacuum pumps are used in controlled atmosphere packaging (CAP) systems in the food industry. CAP involves modifying the gas composition within food packaging to extend the shelf life and maintain the quality of perishable products. Vacuum pumps aid in the removal of oxygen or other unwanted gases from the package, allowing the introduction of a desired gas mixture that preserves the food’s freshness and inhibits microbial growth.

These are just a few examples of how vacuum pumps are used in food processing. The ability to create and control vacuum or low-pressure environments is a valuable asset in preserving food quality, enhancing shelf life, and facilitating various processing techniques in the food industry.

editor by Dream 2024-05-08

China high quality DC 24V Inflatable Circulating Electric Mini Diaphragm Vacuum Air Pump vacuum pump booster

Product Description

DC 24V Inflatable Circulating Electric Mini Diaphragm Vacuum Air Pump

Product Feature:

1. Small, powerful

2. Look attractive, durable Shell

3. Chemical stability, oil-free dry-running, maintenance-free

4. Long life

5. Good sealing, low noise

Technical Parameter:

| Rated woltege | 12V | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Rated power | 3.6w | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Max pressure | 1.5bar | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Max current | 3 China, HangZhou, ZHangZhoug, China.

ONEREEL is specialized in the design and manufacture Steel Spools, Plastic Spools, Cable roller, Yarn Bobbin, aluminum spool , Cable Reel Stand, Sheave Pulley, Cable Conveyor, Hydraulic Puller Tensioner, Gin Poles, Cable Pulling Winch, Safety Tools, Wire Grip, Plastic Parts, and Pump in the industry since 1991. All of our customer spool and wire carrier are engineered and manufactured in our 120,000 square foot state-of-the-art manufacturing plant located in HangZhou, ZHangZhoug.

Hot Product

Our Customer

Packaging & Transportation

Authoritative Certificate

FAQ Q1: Can I get samples? /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What Is the Vacuum Level and How Is It Measured in Vacuum Pumps?The vacuum level refers to the degree of pressure below atmospheric pressure in a vacuum system. It indicates the level of “emptiness” or the absence of gas molecules in the system. Here’s a detailed explanation of vacuum level measurement in vacuum pumps: Vacuum level is typically measured using pressure units that represent the difference between the pressure in the vacuum system and atmospheric pressure. The most common unit of measurement for vacuum level is the Pascal (Pa), which is the SI unit. Other commonly used units include Torr, millibar (mbar), and inches of mercury (inHg). Vacuum pumps are equipped with pressure sensors or gauges that measure the pressure within the vacuum system. These gauges are specifically designed to measure the low pressures encountered in vacuum applications. There are several types of pressure gauges used for measuring vacuum levels: 1. Pirani Gauge: Pirani gauges operate based on the thermal conductivity of gases. They consist of a heated element exposed to the vacuum environment. As gas molecules collide with the heated element, they transfer heat away, causing a change in temperature. By measuring the change in temperature, the pressure can be inferred, allowing the determination of the vacuum level. 2. Thermocouple Gauge: Thermocouple gauges utilize the thermal conductivity of gases similar to Pirani gauges. They consist of two dissimilar metal wires joined together, forming a thermocouple. As gas molecules collide with the thermocouple, they cause a temperature difference between the wires, generating a voltage. The voltage is proportional to the pressure and can be calibrated to provide a reading of the vacuum level. 3. Capacitance Manometer: Capacitance manometers measure pressure by detecting the change in capacitance between two electrodes caused by the deflection of a flexible diaphragm. As the pressure in the vacuum system changes, the diaphragm moves, altering the capacitance and providing a measurement of the vacuum level. 4. Ionization Gauge: Ionization gauges operate by ionizing gas molecules in the vacuum system and measuring the resulting electrical current. The ion current is proportional to the pressure, allowing the determination of the vacuum level. There are different types of ionization gauges, such as hot cathode, cold cathode, and Bayard-Alpert gauges. 5. Baratron Gauge: Baratron gauges utilize the principle of capacitance manometry but with a different design. They consist of a pressure-sensing diaphragm separated by a small gap from a reference electrode. The pressure difference between the vacuum system and the reference electrode causes the diaphragm to deflect, changing the capacitance and providing a measurement of the vacuum level. It’s important to note that different types of vacuum pumps may have different pressure ranges and may require specific pressure gauges suitable for their operating conditions. Additionally, vacuum pumps are often equipped with multiple gauges to provide information about the pressure at different stages of the pumping process or in different parts of the system. In summary, vacuum level refers to the pressure below atmospheric pressure in a vacuum system. It is measured using pressure gauges specifically designed for low-pressure environments. Common types of pressure gauges used in vacuum pumps include Pirani gauges, thermocouple gauges, capacitance manometers, ionization gauges, and Baratron gauges. \ Can Vacuum Pumps Be Used for Soil and Groundwater Remediation?Vacuum pumps are indeed widely used for soil and groundwater remediation. Here’s a detailed explanation: Soil and groundwater remediation refers to the process of removing contaminants from the soil and groundwater to restore environmental quality and protect human health. Vacuum pumps play a crucial role in various remediation techniques by facilitating the extraction and treatment of contaminated media. Some of the common applications of vacuum pumps in soil and groundwater remediation include: 1. Soil Vapor Extraction (SVE): Soil vapor extraction is a widely used remediation technique for volatile contaminants present in the subsurface. It involves the extraction of vapors from the soil by applying a vacuum to the subsurface through wells or trenches. Vacuum pumps create a pressure gradient that induces the movement of vapors towards the extraction points. The extracted vapors are then treated to remove or destroy the contaminants. Vacuum pumps play a vital role in SVE by maintaining the necessary negative pressure to enhance the volatilization and extraction of contaminants from the soil. 2. Dual-Phase Extraction (DPE): Dual-phase extraction is a remediation method used for the simultaneous extraction of both liquids (such as groundwater) and vapors (such as volatile organic compounds) from the subsurface. Vacuum pumps are utilized to create a vacuum in extraction wells or points, drawing out both the liquid and vapor phases. The extracted groundwater and vapors are then separated and treated accordingly. Vacuum pumps are essential in DPE systems for efficient and controlled extraction of both liquid and vapor-phase contaminants. 3. Groundwater Pumping and Treatment: Vacuum pumps are also employed in groundwater remediation through the process of pumping and treatment. They are used to extract contaminated groundwater from wells or recovery trenches. By creating a vacuum or negative pressure, vacuum pumps facilitate the flow of groundwater towards the extraction points. The extracted groundwater is then treated to remove or neutralize the contaminants before being discharged or re-injected into the ground. Vacuum pumps play a critical role in maintaining the required flow rates and hydraulic gradients for effective groundwater extraction and treatment. 4. Air Sparging: Air sparging is a remediation technique used to treat groundwater and soil contaminated with volatile organic compounds (VOCs). It involves the injection of air or oxygen into the subsurface to enhance the volatilization of contaminants. Vacuum pumps are utilized in air sparging systems to create a vacuum or negative pressure zone in wells or points surrounding the contaminated area. This induces the movement of air and oxygen through the soil, facilitating the release and volatilization of VOCs. Vacuum pumps are essential in air sparging by maintaining the necessary negative pressure gradient for effective contaminant removal. 5. Vacuum-Enhanced Recovery: Vacuum-enhanced recovery, also known as vacuum-enhanced extraction, is a remediation technique used to recover non-aqueous phase liquids (NAPLs) or dense non-aqueous phase liquids (DNAPLs) from the subsurface. Vacuum pumps are employed to create a vacuum or negative pressure gradient in recovery wells or trenches. This encourages the movement and extraction of NAPLs or DNAPLs towards the recovery points. Vacuum pumps facilitate the efficient recovery of these dense contaminants, which may not be easily recoverable using traditional pumping methods. It’s important to note that different types of vacuum pumps, such as rotary vane pumps, liquid ring pumps, or air-cooled pumps, may be used in soil and groundwater remediation depending on the specific requirements of the remediation technique and the nature of the contaminants. In summary, vacuum pumps play a vital role in various soil and groundwater remediation techniques, including soil vapor extraction, dual-phase extraction, groundwater pumping and treatment, air sparging, and vacuum-enhanced recovery. By creating and maintaining the necessary pressure differentials, vacuum pumps enable the efficient extraction, treatment, and removal of contaminants, contributing to the restoration of soil and groundwater quality.

Can Vacuum Pumps Be Used in the Medical Field?Yes, vacuum pumps have a wide range of applications in the medical field. Here’s a detailed explanation: Vacuum pumps play a crucial role in various medical applications, providing suction or creating controlled vacuum environments. Here are some key areas where vacuum pumps are used in the medical field: 1. Negative Pressure Wound Therapy (NPWT): Vacuum pumps are extensively utilized in negative pressure wound therapy, a technique used to promote wound healing. In NPWT, a vacuum pump creates a controlled low-pressure environment within a wound dressing, facilitating the removal of excess fluid, promoting blood flow, and accelerating the healing process. 2. Surgical Suction: Vacuum pumps are an integral part of surgical suction systems. They provide the necessary suction force to remove fluids, gases, or debris from the surgical site during procedures. Surgical suction helps maintain a clear field of view for surgeons, enhances tissue visualization, and contributes to a sterile operating environment. 3. Anesthesia: In anesthesia machines, vacuum pumps are used to create suction for various purposes: – Airway Suction: Vacuum pumps assist in airway suctioning to clear secretions or obstructions from the patient’s airway during anesthesia or emergency situations. – Evacuation of Gases: Vacuum pumps aid in removing exhaled gases from the patient’s breathing circuit, ensuring the delivery of fresh gas mixtures and maintaining appropriate anesthesia levels. 4. Laboratory Equipment: Vacuum pumps are essential components in various medical laboratory equipment: – Vacuum Ovens: Vacuum pumps are used in vacuum drying ovens, which are utilized for controlled drying or heat treatment of sensitive materials, samples, or laboratory glassware. – Centrifugal Concentrators: Vacuum pumps are employed in centrifugal concentrators to facilitate the concentration or dehydration of biological samples, such as DNA, proteins, or viruses. – Freeze Dryers: Vacuum pumps play a vital role in freeze-drying processes, where samples are frozen and then subjected to vacuum conditions to remove water via sublimation, preserving the sample’s structure and integrity. 5. Medical Suction Devices: Vacuum pumps are utilized in standalone medical suction devices, commonly found in hospitals, clinics, and emergency settings. These devices create suction required for various medical procedures, including: – Suctioning of Respiratory Secretions: Vacuum pumps assist in removing respiratory secretions or excess fluids from the airways of patients who have difficulty coughing or clearing their airways effectively. – Thoracic Drainage: Vacuum pumps are used in chest drainage systems to evacuate air or fluid from the pleural cavity, helping in the treatment of conditions such as pneumothorax or pleural effusion. – Obstetrics and Gynecology: Vacuum pumps are employed in devices used for vacuum-assisted deliveries, such as vacuum extractors, to aid in the safe delivery of babies during childbirth. 6. Blood Collection and Processing: Vacuum pumps are utilized in blood collection systems and blood processing equipment: – Blood Collection Tubes: Vacuum pumps are responsible for creating the vacuum inside blood collection tubes, facilitating the collection of blood samples for diagnostic testing. – Blood Separation and Centrifugation: In blood processing equipment, vacuum pumps assist in the separation of blood components, such as red blood cells, plasma, and platelets, for various medical procedures and treatments. 7. Medical Imaging: Vacuum pumps are used in certain medical imaging techniques: – Electron Microscopy: Electron microscopes, including scanning electron microscopes and transmission electron microscopes, require a vacuum environment for high-resolution imaging. Vacuum pumps are employed to maintain the necessary vacuum conditions within the microscope chambers. These are just a few examples of the wide-ranging applications of vacuum pumps in the medical field. Their ability to create suction and controlled vacuum environments makes them indispensable in medical procedures, wound healing, laboratory processes, anesthesia, and various other medical applications.

China high quality Roots Liquid-Ring Water Piston Rotary Vane Dry Portable Screw Scroll Reciprocating Diaphragm Positive Displacement Industrial Air Small Centrifugal Vacuum Pump wholesalerProduct Description

Roots Liquid-ring water piston Rotary vane Dry portable Screw scroll Reciprocating diaphragm positive displacement industrial air small centrifugal vacuum pump Application of vacuum pump Vacuum pumps are used in a wide variety of applications, including:

Vacuum pumps work by removing air and other gases from a chamber. This can be done in a variety of ways, but the most common method is to use a rotating impeller that creates a vacuum. The benefits of using a vacuum pump include:

The disadvantages of using a vacuum pump include:

Overall, vacuum pumps are a versatile and reliable component that can be used in a wide variety of applications. They offer a number of advantages, including reduced pressure, improved air quality, increased efficiency, and reduced costs. However, they also have some disadvantages, such as noise and vibration.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What Are the Typical Applications of Piston Vacuum Pumps?Piston vacuum pumps find applications in various industries and processes. Here’s a detailed explanation of the typical applications of piston vacuum pumps: 1. Laboratories and Research Facilities: – Piston vacuum pumps are commonly used in laboratories and research facilities for a wide range of applications. – They are utilized in vacuum ovens, freeze dryers, vacuum filtration systems, and other equipment requiring controlled evacuation. 2. Pharmaceuticals and Biotechnology: – In the pharmaceutical and biotechnology industries, piston vacuum pumps are employed for processes such as solvent evaporation, distillation, and filtration. – They are used in drug manufacturing, vaccine production, and research involving biochemistry and molecular biology. 3. Food Processing and Packaging: – Piston vacuum pumps play a vital role in the food processing and packaging industry. – They are used in vacuum packaging machines to remove air from packaging containers, extending the shelf life of food products. 4. HVAC and Refrigeration Systems: – Piston vacuum pumps are utilized in HVAC (Heating, Ventilation, and Air Conditioning) systems and refrigeration systems. – They help evacuate air and moisture from the systems to achieve the desired pressure and prevent contamination. 5. Manufacturing and Industrial Processes: – Piston vacuum pumps are employed in various manufacturing and industrial processes. – They are used for degassing, vacuum impregnation, vacuum drying, and other applications that require controlled evacuation. 6. Automotive Industry: – In the automotive industry, piston vacuum pumps are often used in brake booster systems. – They create a vacuum to assist in brake actuation, providing the necessary power for braking. 7. Electronics and Semiconductor Manufacturing: – Piston vacuum pumps are utilized in electronics and semiconductor manufacturing processes. – They help create a controlled environment with low-pressure conditions during the production of microchips, integrated circuits, and other electronic components. 8. Environmental Monitoring and Analysis: – Piston vacuum pumps are utilized in environmental monitoring and analysis equipment. – They are used in air sampling devices, gas analyzers, and other instruments that require precise vacuum control. 9. Scientific Research and Vacuum Systems: – Piston vacuum pumps are employed in various scientific research applications. – They are used in vacuum systems for particle accelerators, electron microscopes, mass spectrometers, surface analysis instruments, and other scientific equipment. In summary, piston vacuum pumps have diverse applications in laboratories, pharmaceuticals, food processing, HVAC systems, manufacturing processes, automotive industry, electronics, environmental monitoring, scientific research, and more. Their ability to provide controlled evacuation and achieve moderate vacuum levels makes them suitable for a wide range of industries and processes.

What Are the Safety Precautions for Operating Piston Vacuum Pumps?Operating piston vacuum pumps requires adherence to safety precautions to ensure the well-being of personnel and the proper functioning of the equipment. Here’s a detailed explanation of the safety precautions for operating piston vacuum pumps: – Familiarize Yourself with the User Manual: Before operating a piston vacuum pump, thoroughly read and understand the user manual provided by the manufacturer. The manual contains important safety guidelines specific to the pump model. – Personal Protective Equipment (PPE): Always wear appropriate personal protective equipment, such as safety goggles, gloves, and hearing protection, when operating the pump. This helps protect against potential hazards, including chemical exposure, flying debris, and noise. – Ventilation: Ensure that the area where the pump is operated has adequate ventilation. Proper ventilation helps prevent the accumulation of fumes, vapors, or hazardous gases that may be generated during the pumping process. – Electrical Safety: Follow electrical safety precautions, including proper grounding and connection of the pump to a suitable power source. Inspect power cords and plugs for any damage before use, and avoid using the pump in wet or damp environments. – Pressure and Vacuum Limits: Operate the pump within its specified pressure and vacuum limits. Exceeding these limits can lead to equipment failure, compromising safety and performance. – Overpressure Protection: Ensure the pump has appropriate overpressure protection mechanisms, such as relief valves or pressure sensors, to prevent excessive pressure buildup. Regularly inspect and maintain these safety devices to ensure their proper functioning. – Cooling and Temperature: Pay attention to the cooling requirements of the pump. Adequate cooling is necessary to prevent overheating and potential damage to the pump. Avoid blocking or obstructing cooling vents or fins. Monitor the pump’s temperature during operation and follow any temperature-related guidelines provided by the manufacturer. – Maintenance and Inspection: Regularly inspect and maintain the pump according to the manufacturer’s recommendations. This includes cleaning, lubricating, and replacing parts as necessary. Perform maintenance tasks only when the pump is turned off and disconnected from the power source. – Emergency Stop: Familiarize yourself with the location and operation of the emergency stop button or switch on the pump. In case of any emergency or abnormal situation, immediately activate the emergency stop to shut down the pump safely. – Training and Competence: Ensure that operators are adequately trained and competent to operate the piston vacuum pump. Proper training helps minimize the risks associated with incorrect operation or handling of the equipment. – Hazardous Materials: If the pump is used with hazardous materials, follow appropriate safety protocols for handling, containment, and disposal. Be aware of the potential risks associated with the materials being pumped and take necessary precautions to mitigate those risks. – Warning Signs and Labels: Pay attention to warning signs, labels, and markings on the pump, including safety instructions, hazard warnings, and operating instructions. Follow these instructions carefully to ensure safe operation. – Emergency Procedures: Establish and communicate clear emergency procedures in case of accidents, spills, or other hazardous situations. Ensure that operators are aware of these procedures and know how to respond appropriately. – Regular Risk Assessment: Conduct regular risk assessments of the pump operation to identify potential hazards and implement appropriate safety measures. Periodically review and update safety protocols based on the results of these assessments. – Emergency Response Resources: Keep appropriate emergency response resources readily available, such as fire extinguishers, spill kits, and emergency eyewash stations, in case of accidents or spills. In summary, operating piston vacuum pumps safely requires following several key safety precautions, including familiarizing yourself with the user manual, using appropriate personal protective equipment, ensuring proper ventilation, adhering to electrical safety guidelines, operating within pressure and vacuum limits, maintaining cooling requirements, performing regular maintenance and inspections, being aware of emergency stop procedures, providing adequate training and competence, handling hazardous materials safely, paying attention to warning signs and labels, establishing emergency procedures, conducting risk assessments, and keeping emergency response resources available.

What Are the Differences Between Single-Stage and Two-Stage Piston Vacuum Pumps?Single-stage and two-stage piston vacuum pumps are two common types of pumps used for creating a vacuum. Here’s a detailed explanation of their differences: 1. Number of Stages: – The primary difference between single-stage and two-stage piston vacuum pumps lies in the number of stages or steps involved in the compression process. – A single-stage pump has a single piston that compresses the gas in one stroke. – In contrast, a two-stage pump consists of two pistons arranged in series, allowing the gas to be compressed in two stages. 2. Compression Ratio: – Single-Stage: In a single-stage piston vacuum pump, the compression ratio is limited to the single stroke of the piston. This means that the pump can achieve a compression ratio of approximately 10:1. – Two-Stage: In a two-stage piston vacuum pump, the compression ratio is significantly higher. The first stage compresses the gas, and then it passes through an intermediate chamber before entering the second stage for further compression. This allows for a higher compression ratio, typically around 100:1. 3. Vacuum Level: – Single-Stage: Single-stage piston vacuum pumps are generally suitable for applications that require moderate vacuum levels. – They can achieve vacuum levels up to approximately 10-3 Torr (millitorr) or in the low micron range (10-6 Torr). – Two-Stage: Two-stage piston vacuum pumps are capable of reaching deeper vacuum levels compared to single-stage pumps. – They can achieve vacuum levels in the high vacuum range, typically down to 10-6 Torr or even lower, making them suitable for applications that require a more extensive vacuum. 4. Pumping Speed: – Single-Stage: Single-stage pumps generally have a higher pumping speed or evacuation rate compared to two-stage pumps. – This means that single-stage pumps can evacuate a larger volume of gas per unit of time, making them suitable for applications that require faster evacuation. – Two-Stage: Two-stage pumps have a lower pumping speed compared to single-stage pumps. – While they may have a slower evacuation rate, they compensate for it by achieving deeper vacuum levels. 5. Applications: – Single-Stage: Single-stage piston vacuum pumps are commonly used in applications that require moderate vacuum levels and higher pumping speeds. – They are suitable for laboratory use, vacuum packaging, HVAC systems, and various industrial processes. – Two-Stage: Two-stage piston vacuum pumps are well-suited for applications that require deeper vacuum levels. – They are commonly used in scientific research, semiconductor manufacturing, analytical instruments, and other processes that demand high vacuum conditions. 6. Size and Complexity: – Single-Stage: Single-stage pumps are generally more compact and simpler in design compared to two-stage pumps. – They have fewer components, making them easier to install, operate, and maintain. – Two-Stage: Two-stage pumps are relatively larger and more complex in design due to the additional components required for the two-stage compression process. – They may require more maintenance and expertise for operation and servicing. In summary, the main differences between single-stage and two-stage piston vacuum pumps lie in the number of stages, compression ratio, achievable vacuum levels, pumping speed, applications, and size/complexity. Selecting the appropriate pump depends on the desired vacuum level, pumping speed requirements, and specific application needs.

China Good quality Low Lift Oil Free Air Vacuum Compressor Duplex Diaphragm Fluid Siphon Pump vacuum pumpProduct Description

Low lift oil free air vacuum compressor duplex diaphragm fluid siphon pump Product Introduction Certificate Company Profile Packing & Shipping FAQ Q1: What’s your business range? More information please contact us, we will provide the timely feedback! /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What Is the Impact of Altitude on Vacuum Pump Performance?The performance of vacuum pumps can be influenced by the altitude at which they are operated. Here’s a detailed explanation: Altitude refers to the elevation or height above sea level. As the altitude increases, the atmospheric pressure decreases. This decrease in atmospheric pressure can have several effects on the performance of vacuum pumps: 1. Reduced Suction Capacity: Vacuum pumps rely on the pressure differential between the suction side and the discharge side to create a vacuum. At higher altitudes, where the atmospheric pressure is lower, the pressure differential available for the pump to work against is reduced. This can result in a decrease in the suction capacity of the vacuum pump, meaning it may not be able to achieve the same level of vacuum as it would at lower altitudes. 2. Lower Ultimate Vacuum Level: The ultimate vacuum level, which represents the lowest pressure that a vacuum pump can achieve, is also affected by altitude. As the atmospheric pressure decreases with increasing altitude, the ultimate vacuum level that can be attained by a vacuum pump is limited. The pump may struggle to reach the same level of vacuum as it would at sea level or lower altitudes. 3. Pumping Speed: Pumping speed is a measure of how quickly a vacuum pump can remove gases from a system. At higher altitudes, the reduced atmospheric pressure can lead to a decrease in pumping speed. This means that the vacuum pump may take longer to evacuate a chamber or system to the desired vacuum level. 4. Increased Power Consumption: To compensate for the decreased pressure differential and achieve the desired vacuum level, a vacuum pump operating at higher altitudes may require higher power consumption. The pump needs to work harder to overcome the lower atmospheric pressure and maintain the necessary suction capacity. This increased power consumption can impact energy efficiency and operating costs. 5. Efficiency and Performance Variations: Different types of vacuum pumps may exhibit varying degrees of sensitivity to altitude. Oil-sealed rotary vane pumps, for example, may experience more significant performance variations compared to dry pumps or other pump technologies. The design and operating principles of the vacuum pump can influence its ability to maintain performance at higher altitudes. It’s important to note that vacuum pump manufacturers typically provide specifications and performance curves for their pumps based on standardized conditions, often at or near sea level. When operating a vacuum pump at higher altitudes, it is advisable to consult the manufacturer’s guidelines and consider any altitude-related limitations or adjustments that may be necessary. In summary, the altitude at which a vacuum pump operates can have an impact on its performance. The reduced atmospheric pressure at higher altitudes can result in decreased suction capacity, lower ultimate vacuum levels, reduced pumping speed, and potentially increased power consumption. Understanding these effects is crucial for selecting and operating vacuum pumps effectively in different altitude environments.

Can Vacuum Pumps Be Used for Chemical Distillation?Yes, vacuum pumps are commonly used in chemical distillation processes. Here’s a detailed explanation: Chemical distillation is a technique used to separate or purify components of a mixture based on their different boiling points. The process involves heating the mixture to evaporate the desired component and then condensing the vapor to collect the purified substance. Vacuum pumps play a crucial role in chemical distillation by creating a reduced pressure environment, which lowers the boiling points of the components and enables distillation at lower temperatures. Here are some key aspects of using vacuum pumps in chemical distillation: 1. Reduced Pressure: By creating a vacuum or low-pressure environment in the distillation apparatus, vacuum pumps lower the pressure inside the system. This reduction in pressure lowers the boiling points of the components, allowing distillation to occur at temperatures lower than their normal boiling points. This is particularly useful for heat-sensitive or high-boiling-point compounds that would decompose or become thermally degraded at higher temperatures. 2. Increased Boiling Point Separation: Vacuum distillation increases the separation between the boiling points of the components, making it easier to achieve a higher degree of purification. In regular atmospheric distillation, the boiling points of some components may overlap, leading to less effective separation. By operating under vacuum, the boiling points of the components are further apart, improving the selectivity and efficiency of the distillation process. 3. Energy Efficiency: Vacuum distillation can be more energy-efficient compared to distillation under atmospheric conditions. The reduced pressure lowers the required temperature for distillation, resulting in reduced energy consumption and lower operating costs. This is particularly advantageous when dealing with large-scale distillation processes or when distilling heat-sensitive compounds that require careful temperature control. 4. Types of Vacuum Pumps: Different types of vacuum pumps can be used in chemical distillation depending on the specific requirements of the process. Some commonly used vacuum pump types include: – Rotary Vane Pumps: Rotary vane pumps are widely used in chemical distillation due to their ability to achieve moderate vacuum levels and handle various gases. They work by using rotating vanes to create chambers that expand and contract, enabling the pumping of gas or vapor. – Diaphragm Pumps: Diaphragm pumps are suitable for smaller-scale distillation processes. They use a flexible diaphragm that moves up and down to create a vacuum and compress the gas or vapor. Diaphragm pumps are often oil-free, making them suitable for applications where avoiding oil contamination is essential. – Liquid Ring Pumps: Liquid ring pumps can handle more demanding distillation processes and corrosive gases. They rely on a rotating liquid ring to create a seal and compress the gas or vapor. Liquid ring pumps are commonly used in chemical and petrochemical industries. – Dry Screw Pumps: Dry screw pumps are suitable for high-vacuum distillation processes. They use intermeshing screws to compress and transport gas or vapor. Dry screw pumps are known for their high pumping speeds, low noise levels, and oil-free operation. Overall, vacuum pumps are integral to chemical distillation processes as they create the necessary reduced pressure environment that enables distillation at lower temperatures. By using vacuum pumps, it is possible to achieve better separation, improve energy efficiency, and handle heat-sensitive compounds effectively. The choice of vacuum pump depends on factors such as the required vacuum level, the scale of the distillation process, and the nature of the compounds being distilled.

What Is a Vacuum Pump, and How Does It Work?A vacuum pump is a mechanical device used to create and maintain a vacuum or low-pressure environment within a closed system. Here’s a detailed explanation: A vacuum pump operates on the principle of removing gas molecules from a sealed chamber, reducing the pressure inside the chamber to create a vacuum. The pump accomplishes this through various mechanisms and techniques, depending on the specific type of vacuum pump. Here are the basic steps involved in the operation of a vacuum pump: 1. Sealed Chamber: The vacuum pump is connected to a sealed chamber or system from which air or gas molecules need to be evacuated. The chamber can be a container, a pipeline, or any other enclosed space. 2. Inlet and Outlet: The vacuum pump has an inlet and an outlet. The inlet is connected to the sealed chamber, while the outlet may be vented to the atmosphere or connected to a collection system to capture or release the evacuated gas. 3. Mechanical Action: The vacuum pump creates a mechanical action that removes gas molecules from the chamber. Different types of vacuum pumps use various mechanisms for this purpose: – Positive Displacement Pumps: These pumps physically trap gas molecules and remove them from the chamber. Examples include rotary vane pumps, piston pumps, and diaphragm pumps. – Momentum Transfer Pumps: These pumps use high-speed jets or rotating blades to transfer momentum to gas molecules, pushing them out of the chamber. Examples include turbomolecular pumps and diffusion pumps. – Entrapment Pumps: These pumps capture gas molecules by adsorbing or condensing them on surfaces or in materials within the pump. Cryogenic pumps and ion pumps are examples of entrainment pumps. 4. Gas Evacuation: As the vacuum pump operates, it creates a pressure differential between the chamber and the pump. This pressure differential causes gas molecules to move from the chamber to the pump’s inlet. 5. Exhaust or Collection: Once the gas molecules are removed from the chamber, they are either exhausted into the atmosphere or collected and processed further, depending on the specific application. 6. Pressure Control: Vacuum pumps often incorporate pressure control mechanisms to maintain the desired level of vacuum within the chamber. These mechanisms can include valves, regulators, or feedback systems that adjust the pump’s operation to achieve the desired pressure range. 7. Monitoring and Safety: Vacuum pump systems may include sensors, gauges, or indicators to monitor the pressure levels, temperature, or other parameters. Safety features such as pressure relief valves or interlocks may also be included to protect the system and operators from overpressure or other hazardous conditions. It’s important to note that different types of vacuum pumps have varying levels of vacuum they can achieve and are suitable for different pressure ranges and applications. The choice of vacuum pump depends on factors such as the required vacuum level, gas composition, pumping speed, and the specific application’s requirements. In summary, a vacuum pump is a device that removes gas molecules from a sealed chamber, creating a vacuum or low-pressure environment. The pump accomplishes this through mechanical actions, such as positive displacement, momentum transfer, or entrapment. By creating a pressure differential, the pump evacuates gas from the chamber, and the gas is either exhausted or collected. Vacuum pumps play a crucial role in various industries, including manufacturing, research, and scientific applications.

China best Energy-Conserving Vacuum Pump Air Rotary Oil Water Piston Dry Portable Mini Scroll Reciprocating Diaphragm Centrifugal Positive Displacement DC AC Vacuum Pumps supplierProduct Description

Energy-Conserving Vacuum Pump Air Rotary Oil Water Piston Dry Portable Mini Scroll Reciprocating Diaphragm Centrifugal Positive Displacement DC AC Vacuum Pumps Vacuum Pumps The installation of a Variable Speed Drive (VSD), sometimes called a variable frequency drive, usually saves between 50 and 65% in electricity costs with the same or better regulation of vacuum. The range of energy savings can be from 30 to 80 percent. They can be adapted to blower or in some cases rotary vane type vacuum pumps. They work by changing the speed of the vacuum pump based on the reading from a pressure sensor that is mounted on the vacuum line near the receiver jar. The VSD is basically a dedicated computer with many adjustments so it may be possible to improve vacuum regulation over the typical pneumatic vacuum regulator that only has a vacuum level adjustment. A VSD for a vacuum pump is usually economical for a dairy that milks a total of 8 hours or more per day. Typically a VSD will not be an economical option for small dairies due to less milking time and thus shorter vacuum pump run times but there are some other options to save energy costs.

company information

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can Piston Vacuum Pumps Create a Deep Vacuum?Yes, piston vacuum pumps have the capability to create a deep vacuum. Here’s a detailed explanation: Piston vacuum pumps are designed to generate and maintain a vacuum by using a reciprocating piston mechanism. They can achieve vacuum levels ranging from millitorr (10-3 Torr) to microns (10-6 Torr), which is considered a deep vacuum range. When the piston moves downward during the suction stroke, it creates a vacuum within the cylinder. This allows gas or air from the system being evacuated to enter the cylinder. As the piston moves up during the compression stroke, the gas is expelled from the cylinder, reducing its volume and increasing its pressure. This cyclic process continues, gradually reducing the pressure within the system. One of the factors that contribute to the ability of piston vacuum pumps to create a deep vacuum is the use of an airtight seal between the piston and cylinder walls. This seal prevents the gas from leaking back into the evacuated system, allowing the pump to maintain the desired vacuum level. It’s important to note that the achievable vacuum level of a piston vacuum pump can depend on various factors, including the design of the pump, the materials used, the quality of the seals, and the operating conditions. Additionally, the flow rate of the pump may be lower compared to other types of vacuum pumps, as piston pumps are typically designed for applications that require low flow rates but high vacuum levels. In summary, piston vacuum pumps can create a deep vacuum in the millitorr to micron range. With their reciprocating piston mechanism and airtight seals, they are capable of generating and maintaining a vacuum suitable for applications that require deep vacuum conditions.

What Is the Energy Efficiency of Piston Vacuum Pumps?The energy efficiency of piston vacuum pumps can vary depending on several factors. Here’s a detailed explanation: 1. Design and Technology: – The design and technology used in piston vacuum pumps can significantly influence their energy efficiency. – Modern piston pump designs often incorporate features such as optimized valve systems, reduced internal leakage, and improved sealing mechanisms to enhance efficiency. – Advancements in materials and manufacturing techniques have also contributed to more efficient piston pump designs. 2. Motor Efficiency: – The motor driving the piston pump plays a crucial role in overall energy efficiency. – High-efficiency motors, such as those adhering to energy efficiency standards like NEMA Premium or IE3, can significantly improve the energy efficiency of the pump. – Proper motor sizing and matching to the pump’s load requirements are also important to maximize efficiency. 3. Control Systems: – The use of advanced control systems can optimize the energy consumption of piston vacuum pumps. – Variable frequency drives (VFDs) or speed control systems can adjust the pump’s operating speed based on the demand, reducing energy consumption during periods of lower demand. – Smart control algorithms and sensors can also help optimize the pump’s performance and energy efficiency. 4. System Design and Integration: – The overall system design and integration of the piston vacuum pump within the application can impact energy efficiency. – Proper sizing and selection of the pump based on the specific application requirements can ensure that the pump operates within its optimal efficiency range. – Efficient piping and ducting design, as well as minimizing pressure losses and leaks, can further improve the overall energy efficiency of the system. 5. Load Profile and Operating Conditions: – The load profile and operating conditions of the piston vacuum pump have a significant impact on energy consumption. – Higher vacuum levels or flow rates may require more energy to be supplied by the pump. – Operating the pump continuously at maximum capacity may lead to higher energy consumption compared to intermittent or variable load conditions. – It’s important to evaluate the specific operating requirements and adjust the pump’s operation accordingly to optimize energy efficiency. 6. Comparing Efficiency Ratings: – When comparing the energy efficiency of different piston vacuum pumps, it can be helpful to look for efficiency ratings or specifications provided by the manufacturer. – Some manufacturers provide efficiency data or performance curves indicating the pump’s energy consumption at various operating points. – These ratings can assist in selecting a pump that meets the desired energy efficiency requirements. In summary, the energy efficiency of piston vacuum pumps can be influenced by factors such as design and technology, motor efficiency, control systems, system design and integration, load profile, and operating conditions. Considering these factors and evaluating efficiency ratings can help in selecting an energy-efficient piston vacuum pump for a specific application.

How Do You Maintain and Service a Piston Vacuum Pump?Maintaining and servicing a piston vacuum pump is essential to ensure its optimal performance and longevity. Here’s a detailed explanation: 1. Regular Inspection: – Perform regular visual inspections of the pump to check for any signs of damage, leaks, or wear. – Inspect the seals, gaskets, and fittings for any cracks or deterioration. – Ensure that all connections are tight and secure. 2. Oil Change: – Piston vacuum pumps typically require regular oil changes to maintain proper lubrication and prevent contamination. – Follow the manufacturer’s guidelines regarding the frequency of oil changes. – Drain the old oil completely and replace it with the recommended oil type and quantity. – Dispose of the used oil according to proper environmental regulations. 3. Filter Replacement: – Many piston vacuum pumps have filters to prevent dust, particles, and contaminants from entering the pump. – Check the filter regularly and replace it as needed to maintain proper airflow and prevent clogging. 4. Cleaning: – Keep the exterior of the pump and its surrounding area clean and free from debris. – Use a soft cloth or brush to remove any dust or dirt accumulation. – Avoid using harsh chemicals or solvents that may damage the pump’s surfaces. 5. Seals and Gaskets: – Inspect the seals and gaskets regularly and replace them if they show signs of wear or damage. – Ensure that the seals provide a proper airtight seal to prevent leaks and maintain vacuum performance. 6. Cooling System: – If the piston vacuum pump has a cooling system, monitor it regularly to ensure proper functioning. – Clean or replace the cooling system components as recommended by the manufacturer. 7. Professional Maintenance: – Consider scheduling professional maintenance and service at regular intervals, especially for more complex or critical applications. – Professional technicians can perform in-depth inspections, conduct performance tests, and address any specific issues or concerns. – They can also provide recommendations on optimizing the pump’s performance and extending its lifespan. 8. Manufacturer Guidelines: – Always refer to the manufacturer’s maintenance and service guidelines specific to your piston vacuum pump model. – Follow their recommendations regarding oil type, oil level, maintenance intervals, and any other specific instructions. – Adhering to the manufacturer’s guidelines ensures proper operation and prevents voiding the warranty. In summary, maintaining and servicing a piston vacuum pump involves regular inspection, oil changes, filter replacement, cleaning, checking seals and gaskets, monitoring the cooling system, and considering professional maintenance. Following the manufacturer’s guidelines is crucial for effective maintenance and to maximize the pump’s performance and lifespan.

China Standard Piston Vacuum Pump Air Rotary Oil Water Rotary Dry Portable Mini Scroll Reciprocating Diaphragm Centrifugal Positive Displacement DC AC Vacuum Pumps vacuum pump for acProduct Description

Piston Vacuum Pump Air Rotary Oil Water Rotary Dry Portable Mini Scroll Reciprocating Diaphragm Centrifugal Positive Displacement DC AC Vacuum Pumps piston vacuum pump Piston type vacuum pumps and compressors are being used where oil-free air is a must. The oil free character of the pump is a guaranty of low maintenance costs. The pumps are available in capacities of maximum 6 m3/hr and they are able to reach a vacuum of 10 mbar(a). Used as a compressor they reach a pressure of approx. 7 bar(g) maximum. These pumps are being used for light industrial works, medical industry, printing and instrument industry, plastic, food and packaging, electronic, chemical and textile industry.

company information

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1